How To Make A Sluice Box

This week I went and asked "how to SIZE a sluice box" to the crew on a big gilded prospector forum and other sluice or gravity gold recovery 'experts' and gathered the list of emails and forum posts here below. As yous will see, in summary, nearly can optimize or troubleshoot a sluice box just few or none tin size a golden sluice box.

_______

I want to procedure ane TPH (60 liters/min) of solids, what size a sluice box ready-up do I need? How much sluicing surface area? How wide, how long should the sluice be?

_______

Following values are recommended in Poling'due south (1989) and Clarkson's (1990) scientific sluice box studies:

– heavy (6mm thick) not-flattened expanded metal riffles demand 2400 ls/min of water per width meter of sluice for to work properly

– i inch high bending atomic number 26 riffles need double quantity i.e. 4800 ls/min of water per width meter of sluice

– the slurry flowing in the box should contain <12% of solids by volume (how much water does a gold sluice need).

Given water volumes are accented minimum volumes, any less will cause gold losses. Exceeding them upward to 50% is not serious.

And so, for 60 ls of solids per minute you would demand (almost) 600 ls/min of water in your expanded metal rifle department which would and so be 25 cm wide. Bending fe section should off course be simply half of that width for proper water flow.

Slurry velocity in sluice should be 1,5 – one,8 m/south for expanded department and 1,8 – 2,2 m/south for bending atomic number 26.

How long? Well, in these studies they used virtually 2,5 m long riffle sections with 2 m long slick plates before each section for to give time to heavies to driblet to the bottom of the box before they hit riffles.

The studies were made for commercial scale operations. I would recommend that you read them by yourself and brand your conclusions. Anyway these are only scientific studies made about the subject this far. All the residue is just commercials and opinions.

What Bending Should a Gold Sluice Be Operated At

______

It's ane TPH of solids at SG 2.8 –> yard kg/hr at 12% Solids = 1000/.12 – 1000 + 1000/2.8 = 7700 l/hr = 128 l/min is my diluted flow feeding the sluice.

From there, 128/2400 ten 100 = v-6 cm wide

Where am I going incorrect? How to SIZE a sluice?

_______

Starting time consideration is, what is the character of the material you will be putting through your sluice?

Poling and Hamilton's work is for auto fed operations.

Your desire for 1 TPH is roughly 2/3rds cubic yards an hour.

Placer is ordinarily figured by cubic yards or meters. Hard-rock is in tons/tonnes.

That beingness said, 2/3CY is right at the limit for hand-fed operations.

This equates to roughly v-6CY/long mean solar day.

Now the bigger question is, "Can this be done every day?"

Only if the person is young, in excellent shape and the material is small enough to fit on a shovel.

Large cobbles and boulders (>12-15cm) will slow your feed charge per unit considerably.

Now we accept to know the probable size range of the gold in your eolith.

The reason behind this is why run grossly over-size non-gold through the sluice?

Grossly over-size requires more water at a higher velocity to clear it from the sluice.

This makes recovery of small gold drib substantially due to uncontrolled turbulence caused by over-size material.

Yous might likewise be interested to know we have recently performed a review of the very best sluice box as of 2021 and beyond.

Then knowing the character of the textile and the required maximum feed classification will give you lot the bodily feed in cubic.

There is every probability that unless yous are feeding straight sand off a embankment, your actual feed for two/3 CY per hour (18 cubic feet) bank-run might be as low as 2-3 cubic feet per hour. How do I know this? I actually accept hand classified fabric (-four mesh) in my area and measured it by weight. ~10 lbs per #2 shovel load with 3300 lbs per cubic yard.

Now as you haven't mentioned anything other than sluice, the question then becomes i of, "What are you going to apply for washing the cloth?"

Straight bank run will require a substantially longer sluice than well washed material.

Clay seems to have an affinity for small gilded. Information technology glomps on and doesn't want to let loose. The clay also sticks to the rocks, so you have rocks coated with clay and a few sprinkles of gold as well. Why feed gold into a sluice only to loose it off the cease.

All this being said, the typical size for a paw-fed sluice and high-broker is ten″ wide. Classifying smaller than one/four″ slows the operation down substantially (yeah, there are a few work-around). Very few folks tin effectively employ sluices larger than 12″ in manus fed operations. Water requirements are nearly 28-30 gpm with more than being ameliorate. You lot can always cut dorsum on the pump'due south throttle.

If y'all are classifying downwards to i/4″, water requirements tin exist lower but pressure must get higher to effectively wash the feed.

As an example, I classify to ane/4″, my pump'southward maximum output is 28-30gpm, but at the pressure required for effective washing reduces the volume to fifteen-20gpm. Meliorate quality pumps should evidence a pump curve in the manual. Most of my sluices are 10″ wide and few are longer than 3 feet.

Be sure to check the regulations in your state or province for what is or is not legal.

I gave all this due to your asking the almost bones question making me retrieve you are relatively new to the business/hobby.

That being said, learn to finer use a gold pan first. The pan is the most constructive recovery device fabricated and is an integral tool for sampling a deposit for economic science. If you have a significant other, spending money on tools that won't pay their way is a quick style to notice interpersonal conflict. Sampling will reduce the probability of said conflict. If you tin can't get at least 5-x grains a twenty-four hours with a pan, walk away from the eolith. At today's spot toll (~$1090 USD), 5 grains is about $7USD. Using a high-broker might raise your daily gross to $50-70 for the same deposit. I want to emphasize that that is GROSS non net. You have to strip out all the expenses, gas for the pump, amortization of the equipment, transportation costs, food and beverage that you bought for the trip, etc.

Hope and dreams are not an constructive strategy to avoid interpersonal disharmonize at abode.

Sample with a pan. Sample with a pan over and over again. There are many folks that tin can consistently brand beans with a pan. A few can process well over a cubic grand of bank-run a twenty-four hours. $10-$12 for the pan versus $600-$g for a loftier-banker and pump. Remember about information technology, for someone experienced $ten for 1CY/day versus $600 for 5CY/solar day.

Besides by using a pan for sampling, it is easy to combine that with a scrap of line-fishing as well. Bringing home a stringer of fish is a lot amend for a relationship than stating, "There, right there, meet those 6 flakes", when all yous pregnant other sees is a depleting banking company account.

_______

I read from your post that you would feed 60 liters per minute. At present i sympathise that your feed rate is non 60 but vi litres per minute. Sorry for my mistake.

Use of the values mentioned in those studies would exist in-applied in your case i suppose.

I have 15 cm wide angle iron riffle sluice-box followed past 30 cm wide expanded metal sluice box, 1000 50/min water pump and six men shovelling dirt into flume. My practical feed charge per unit is about 60 litres per minute. Information technology works well.

_______

Past my opinion, this would require a tabular array of some kind rather than a sluice box, a Miller, shaker or moving ridge table. At least i know that Miller tables are adept in catching flaky gold and particles coming out of ball manufactory will exist flaky. Miller table is cheap and easy to make DIY but requires a person all the time. For vi litre per minute feed the tabular array should be two meters wide at least and that would be hard to handle for one person.

——————

It is not half-dozen 50/m it is 128 l/m

Tables has slimes and fines.

And so, a 6″ sluice 10 x′ long? How did I SIZE this sluice?

_______

My suggestion is to give Doctor at GoldHog in the United states of america a telephone call – explain what you lot are doing and pick his brain. I have non talked to him directly, but heard him on a radio evidence and accept watched all his videos with interest. He knows what he is talking about. He constantly tests and develops placer equipment. On the radio show, he told people to talk to him direct with their circumstances and he would provide his input. There are many factors to consider, non just sluice size – changing upwardly one thing volition impact other things.

My suggestion is to give Doctor at GoldHog in the United states of america a telephone call – explain what you lot are doing and pick his brain. I have non talked to him directly, but heard him on a radio evidence and accept watched all his videos with interest. He knows what he is talking about. He constantly tests and develops placer equipment. On the radio show, he told people to talk to him direct with their circumstances and he would provide his input. There are many factors to consider, non just sluice size – changing upwardly one thing volition impact other things.

At the stop of the day, test your tailings to come across what is being lost and make the necessary adjustments. If you are building something from scratch, then a full general rule is longer is better if y'all have the h2o volume to run it.

_______

I see I assumed this was placer.

As the subject has at present moved outside my area of expertise, all I can offer is an opinion based upon my limited understanding.

With the grind to 200 mesh @ 1tph, I don't recollect a sluice is the best recovery device.

The reasons are:

200 mesh is 75 microns. At that size, nearly whatever turbulence in the water will go along the gold in break.

Now granted, 200 mesh is the screen size and there is always some over-grind. So anything larger than 200 mesh is sent back around while the -200 is passed.

200 mesh makes a serious slurry and if at that place is much feldspar in the grind, you are gonna go dirt. Clay and sluice boxes don't get along well when the feed is a thick slurry.

Lengthening the box brings in a periodic transverse current that reintroduces turbulence in the flow. The full general flow in a sluice should be as laminar as possible to permit gravity to be the major influence in material send. Y'all want controlled turbulence at the bed. This turbulence, similar any other, reduces the velocity of the h2o right upwardly against information technology. Then the problem is you have a real pocket-size particle of golden that falls relatively tedious through a stable water, now being in a flowing water column. Considering of its size and weight, ant turbulence keep the particle either in suspension or in long skips. This argues for a longer sluice to catch the skippers. Merely there is that periodic turbulence reintroducing more than turbulence. It is a catch-22. Longer to catch, but reintroduce turbulence which requires longer.

So not just a sluice, I don't think any of the standard gravity devices is a adept thought.

Now if you lot consider enhanced gravity devices, I call up you could achieve loftier recoveries and a reasonable throughput.

Bowls come to mind.

Introducing higher gravity permits lots more turbulence and creates a far college difference in effective specific gravity.

Think about information technology for a moment. Keeping this simple past illustration, at 1 gravity, a 5kg box is 4kg heavier than a 1kg box.

At 10 gravities, the 5kg box now weighs 50kg and the 1kg box is 10kg with a 40kg difference. Higher gravity makes even slight differences in S.G. become substantial differences in effective S.1000.

There is as well the elutriation tank. Supposedly quite constructive every bit long as the material is small and the classification range is somewhat narrow. From my agreement, these are relatively easy to tune for maximum recovery.

Then there is the hydrocyclone. I have a couple, three reports on their utilise published by the MIRL University of Alaska Fairbanks. They are also available on the web. Looks to be real effective with a fairly loftier purchase cost. Tuning appears to be balancing act and the feed requirements fairly narrow.

Please empathize one more time, my areas of expertise are panning and paw-fed sluices predominantly in the class of loftier-bankers. Everything else is purely opinion with but some to no applied experience.

_______

Thanks,

information technology bring me dorsum to the original question which I will reformulate:

What size of sluice is needed to to procedure 1 TPH of solids at SG 2.8 produced from hard-rock mining. Allow'due south grind it to P80 = 150 mesh

–> 1000 kg/hour at 12% Solids = 1000/.12 – 1000 + 1000/ii.8 = 7700 50/hr = 128 l/min (18 gpm) is my diluted menses feeding the sluice.

_______

THE (repeat THE) all-time info for your specific question is that put up past Sunshine — telephone call (or email) to discuss your specific situation with "Doc" at Gold Hog. Their matting is able to capture the very small sizes of Gold (I accept personally seen -100 easily captured) —– all the same —– there are other considerations like specific flow rates of h2o and processing a specific type textile (all small particle slurry) that are unique to you lot.

We who dwell hither, and every bit information technology is in most all other forums, are not really familiar with hard stone recovery techniques. Recovery of small Gilt sizes, yes, but not 128 L/minute of very fine slurry (or was that just the solids?) of the blazon composition you mention.

_______

128 fifty/min is slurry.

_______

Then yous have 128 L/Min, which is 7,680 L/Hr, which is 2030 Gal/Hr.

Golden Hog mats use ~ 100+- Gal/60 minutes per inch of sluice width for roughly classified banking company run material. Considering you lot are using a highly classified particle size the "usual" numbers probably do not hold up — notwithstanding — IF they did, and then:

The magic number sized width of sluice (using Golden Hog Mats) would be ~ twenty″ wide. Realizing that the Pig Mats come in 36″ widths and it is recommended for commercial operations to go to 18″ for ease of treatment I would say get with eighteen″ width and back off a little on the input material into the slurry. Which of the half dozen mats to use? Go to the source – Doctor.

Now, other systems of recovery (Carpets, Moss, Drops, Hungarian Riffles, Expanded Metal, Lath etc) information technology'southward whatsoever body'southward approximate.

Now every bit to length of the sluice box – I would guess about 8 feet long. Why? Offsetting factors – tightly classified slurry and small Gold. At present I accept to gauge here, whereas others who work with this 'stuff' every day tin give a stronger answer. Over again, go to Md to inquire this type of specific question. A proper reply needs specific experience. You're non committing yourself to buying in on his organization — yous're simply learning from him.

I other thing — this entire string is revolving around numbers. Mining is taught in schools in the just way they tin – "hard" numbers and formulae. Those who mine take the things they did learn in schools and use that base of operations to become bodily hands-on knowledge then, as experience evolves, successful production. There are an infinite number of variables in play while mining — sometimes you just accept to "feel the force" in the Yoda _______

OK now,

I actually shouldn't exist getting into this, but some fundamental things need to be highlighted hither.

Y'all want to process ii,000 pounds of -150 rock per 60 minutes with 240 US gallons of water – How many gallons in 1 ton of h2o . TO ME, that would demand at least a lot more volume of water to process that slurry. A Ton to Ton ratio of solids to water is like trying to procedure adequately thin tooth paste!

What are you using now? Width of your sluice, water catamenia and feed rate, drop of the sluice and recovery medium.With ground upwardly stone of this small bore you should not exist worried with having to classify your input textile! Yahoo!! Hither is an idea of the various "stock" highbankers and their feed rates (depository financial institution run material), http://www.flipsnack.com/goldhog/gold-hog-sluice-matting-product-itemize.html

Capture the tailings and test for losses. No losses, increase feed rate and pitch of the sluice until you go losses (and then dorsum off a niggling).

A mayhap way to look at this is to pump into a test sluice of, oh jeez, say 18 inches broad. 8 feet long and at about 11 – xiii degrees of pitch. At 1,800 gallons of water per hour (picket the Gold Hog videos to run into what 'things' should await similar) it won't have long to figure things out.

https://www.youtube.com/user/georgiagoldguy/videos

Met, you accept to design your arrangement to provide either bones material feed rate or water volume as a outset to the recovery system. If 1 TPH is your actual starting criteria and so make everything else match that starting point. If yous accept to increase the h2o (60% solids is VERY loftier as I see it) so practise information technology.

_______

Mike (from Gold-Hog) was answering his questions from his inquires at our website.

I check every reply that goes through the system and sort of felt the same equally he did.

There was no real "starting bespeak" for the organisation and we really don't spec out entire recovery systems.

Nosotros base a matting configs on known values mainly looking at material run, water volume, sluice width, length, delivery method into the sluice, etc.

Hence the need for Ix mats………..

Burdensome / hard-rock / milling ops take different needs than placer ops.

Many larger ops besides treat their ore in several stages. Med shell, fine crush, and super fine, etc.

In the final stages, the water needs to very soft, shallow, and very limited turbulence.

I would say 100 – 200 gallons per inch then suit the pitch until fine tuned.

Nevertheless, as pointed out before, 150 – 300 mesh gilt can remain suspended if not tuned properly.

When you lot become really fine…….. a different process is used.

That being said………

At the 100 – 150 mesh range……….

100 – 150 gallons per inch width running alternating Razorback and Downwardly Typhoon would do a good job.

I might fifty-fifty first the system with moss and i/ii″ expanded for a few anxiety, then switch over to mats.

It'southward e'er proficient to offer gold LOTS of choices where it can hide.

_______

1000 gpm for a unit of measurement that'southward only processing a ton per hour of very fine sand and/or grindings seems unnecessary and imbalanced. We easily process several yards of gravel per hour with a 12" broad sluice box on 120 to 150 gpm.

If you can't reduce h2o flow, I'd recommend a box in the 26" width for very fine cloth. Maybe i of our 8" Dredge sluice boxes, with a slightly different riffle profile and ii dampers to aid intermission surface tension for ultra fine material.

To run fines on as little as 18 gpm, you should starting time off with a sluice box no narrower than 8" and no wider than 10". Every bit for length, maybe something in the vi′ to 8′ range. Yet, you won't be able to effectively procedure a ton per hour of 150 mesh fabric and maintain a high charge per unit of recovery.

With such a limited h2o flow rate, y'all'll use a relatively narrow sluice box in lodge to have adequate water speed and depth over the riffle set.

With fabric this fine, you'll need to feed information technology at a slow, steady stride (due to the lack of water flow) in order to prevent the riffles from condign overwhelmed at times from an inconsistent feed and/or overfeeding.

_______

THE Finish OFHow to SIZE a Sluice Box

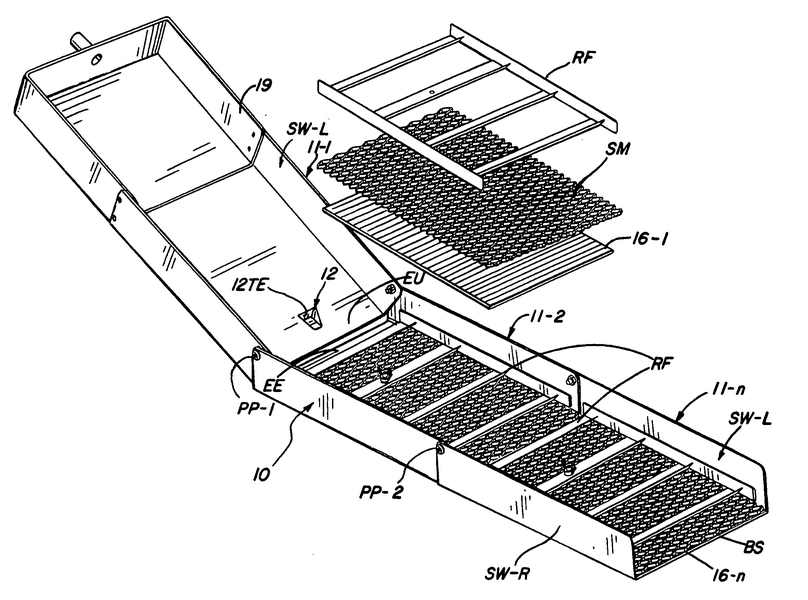

sluice box design

Yous might acquire more at http://www.instructables.com/id/A-recirculating-sluice-box-for-gold-prospecting/ and http://www.google.com/patents/US20120000834

Optimum Slope of a sluice

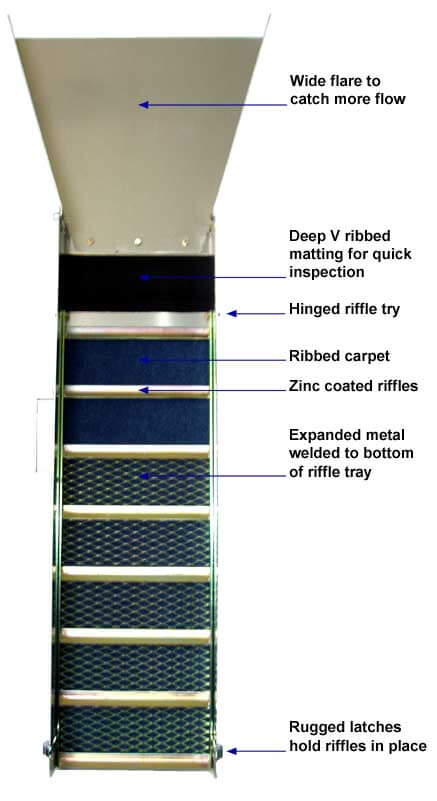

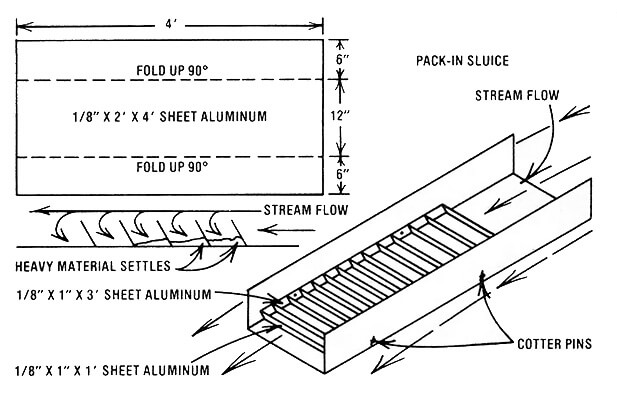

Slope of a sluice is more often than not in the range of 1.3 cm (i/2 in.) to iii.viii cm (1-1/2 in.) per 30.5 cm (ane ft), depending on the size rock in the feed. To motility the larger rocks down the sluice requires a steeper slope or more h2o, both of which cause greater golden losses. Any number of types of collectors tin

be used in a sluice. Nigh common is the utilise of astroturf or indoor-outdoor carpeting under expanded metal. These are plastic products which are used in place of the traditional wool carpets, gunny sacks or cocoa matting.

The plastic carpets are much easier to clean and if done thoroughly, take no run a risk of comport-over from one sample to the next. These are lightweight and dry chop-chop.

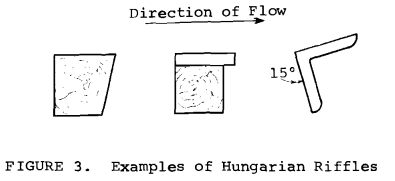

Riffles can be of cross slats of forest or metal, either square wood or metal bars. An comeback on a common riffle is the Hungarian Riffle, which is ane with an overhang, as shown in Figure 3. This over hang gives an eddy in the flow of pulp, thereby assuasive the pocket-sized gold particles a chance to settle. Other riffles can exist of blocks of woods, round tree branches or rocks. I accept seen the floor of a sluice with shallow, staggered v cm (two in.) diameter holes and a little mercury in each. This method is especially good for fine muck containing fine gold. In sum, types of riffles used are a affair of personal preference, or at times, limited past the materials at manus.

Long Tom

A Long Tom is really a diverseness of a sluice. It differs in that it has a ways of screening out gravel and cobble, thereby assuasive less water and a flatter slope. Long Toms are of a wide, curt configuration, and are normally a production machine fed by shovel or wheelbarrow.

Even so, they can be whatsoever size, depending on the samples treated. (SeeFigure 4)

Motorised Sluices

There are any number of machines on the market place with spray-confined over a vibrating screen. The screen, usually 6.4 mm (one/4 in.) or nine.5 mm (three/8 in.) mesh, feeds to a sluice, normally of carpeting and expanded metal. These machines reduce the work load and are faster than a mutual sluice, but still risk the loss of fine golden.

Source: https://www.911metallurgist.com/blog/how-to-size-a-sluice-box

Posted by: hestertoeopla.blogspot.com

0 Response to "How To Make A Sluice Box"

Post a Comment